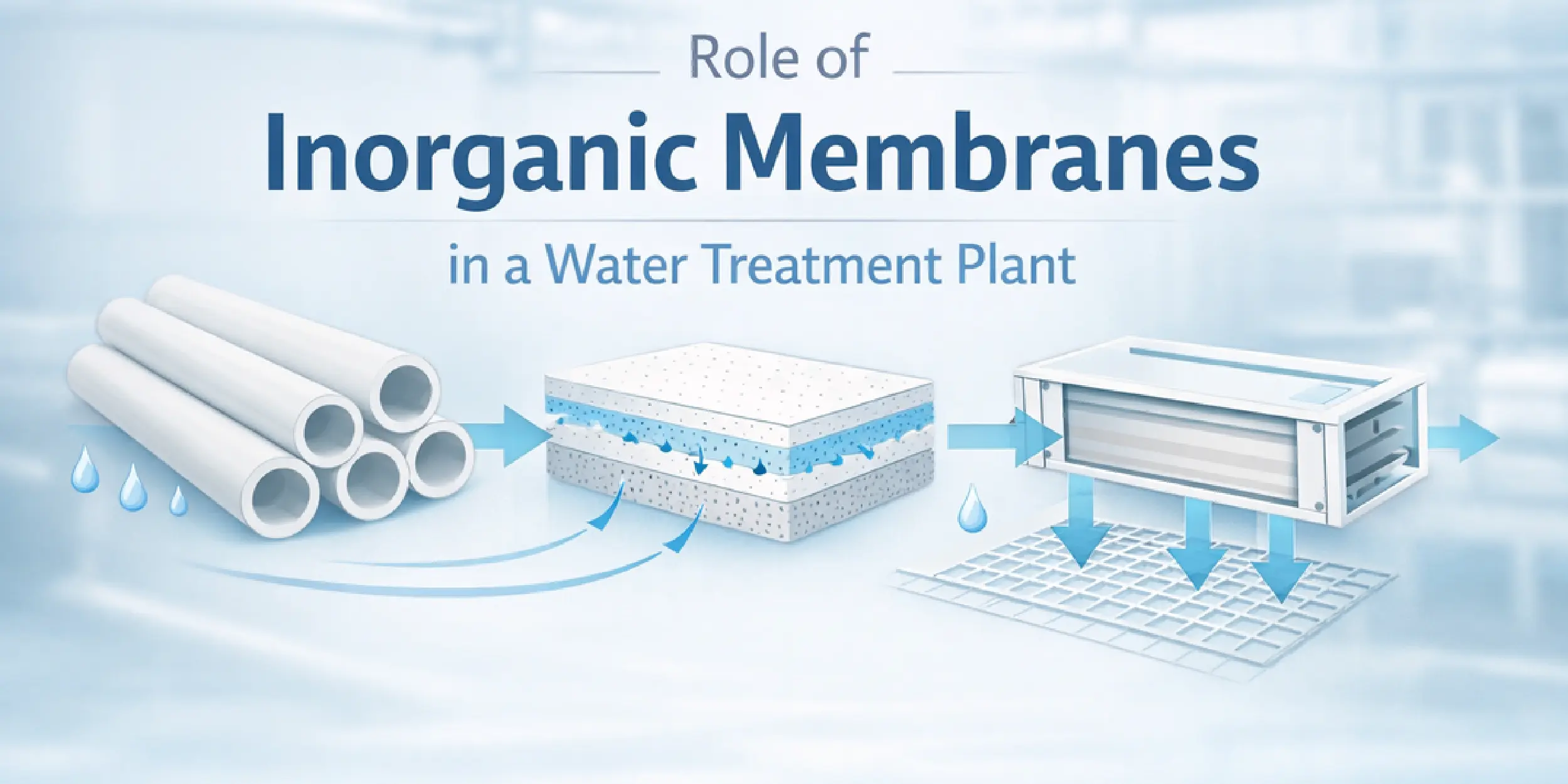

Role of inorganic membranes in a water treatment plant

2024-05-08 | by Joydip Manna

In real Water treatment plants, water purification is rarely about hitting a design number once and forgetting it. It is about surviving bad raw water days without violating limits or shutting down downstream processes. Raw water quality changes with season, rainfall, upstream discharge, industrial load, and even time of day. Clarifiers lose settling efficiency, filters break through unexpectedly, and operators are forced into constant chemical adjustments to maintain stability. Inorganic membranes enter the picture not because plants want complexity, but because they need predictability and control—something increasingly important with tightening norms set by bodies such as the Central Pollution Control Board (CPCB) and State Pollution Control Boards (SPCBs).

From an operational standpoint, inorganic membranes are used when a plant can no longer rely on gravity and biology alone to guarantee consistent water quality. They bring a level of reliability that reduces risk and stabilizes downstream systems, especially in industries that must comply with BIS IS 10500 for potable water or CPCB discharge standards.

How Inorganic Membranes Are Understood on Site

On engineering drawings, inorganic membranes appear as “UF” or “MF blocks.” On site, however, operators understand them as a hard physical barrier—one that does not negotiate with fluctuations in raw water quality.

These membranes are made from ceramic or mineral-based materials with fixed pore structures. Unlike polymer membranes, they do not stretch, swell, shrink, or soften with changes in temperature or chemical exposure. Once installed, their separation limit is permanent. If a particle is larger than the pore, it is physically stopped—every time, without exception.

This makes them fundamentally different from clarifiers or sand filters, which depend on settling velocity, media condition, flow distribution, and accurate chemical dosing to work effectively.

Why Plants Add Membranes Even When Old Systems Exist

Many plants already have clarifiers and sand filters that technically meet standards on paper. The problem is not the average performance—it is the worst-case performance during unpredictable conditions.

Common real-world issues include:

- Sludge carryover during hydraulic surges or sudden flow spikes

- Algae bloom during monsoon or summer causing rapid filter clogging

- Operator errors in coagulant dosing leading to poor floc formation

- Minor power interruptions disturbing settling processes

Inorganic membranes are added to absorb these shocks. They do not fix upstream issues, but they prevent those issues from reaching the outlet and causing compliance failures, especially under strict online monitoring required by CPCB.

This is why many operators describe membranes as “insurance equipment” that protects the plant during its worst days.

What Membranes Actually Remove (and What They Don’t)

Inorganic membranes physically remove:

- Suspended solids and turbidity

- Fine colloidal particles

- Algae and organic debris

- Bacteria, protozoa, and pathogens

They do not remove:

- Dissolved salts or ions

- Water hardness

- Dissolved heavy metals

- Total dissolved solids (TDS)

This distinction is essential in design. Membranes handle physical and microbiological quality. Chemical parameters must be controlled through complementary units like RO, softeners, or specialized polishing systems—especially when meeting WHO Drinking Water Guidelines and BIS IS 10500 requirements.

How They Are Used in a Working Treatment Train

In a functioning plant, membranes are almost never placed at the beginning of the process. They are installed after some form of solids reduction—such as clarification, biological treatment, or coarse filtration.

A typical process sequence looks like this:

- Raw water pretreatment

- Coagulation, flocculation, and clarification (or biological treatment)

- Inorganic membrane filtration for consistent turbidity control

- Disinfection or final polishing (if required)

Water is pushed through the membrane under controlled pressure. Solids accumulate on the surface and are routinely removed by automatic backwashing. When backwashing alone cannot restore flow, chemical cleaning is performed.

Because inorganic membranes are mechanically robust, operators can use stronger cleaning chemicals without risk of media damage.

What Operators Really Monitor Every Day

Inorganic membranes simplify operation but do not eliminate the need for trained monitoring. Operators focus on performance trends rather than isolated numbers.

Key indicators include:

- Gradual rise in transmembrane pressure (TMP)

- Backwash recovery efficiency trends

- Increasing cleaning frequency

- Sudden pressure spikes indicating upstream system failure

When membranes foul faster than expected, the root cause is almost always upstream—chemical issues, poor settling, organic surges, or raw water changes.

Why Inorganic Membranes Suit South Asian Conditions

In India and neighbouring regions, raw water variability is extremely high and operator skill levels vary significantly. In such environments, inorganic membranes perform well because they:

- Handle highly variable raw water without losing stability

- Tolerate aggressive and frequent chemical cleaning

- Fit into compact footprints where space is limited

- Reduce dependency on constant manual chemical adjustments

They are especially useful in river-based systems, industrial intake treatment, and reuse applications where any failure has immediate consequences. Compliance with CPCB, SPCB, and National Green Tribunal (NGT) regulations further increases the role of membrane-based reliability.

Limits That Experienced Engineers Acknowledge

Inorganic membranes are powerful tools, but not shortcuts. They come with certain limitations:

- Higher capital cost compared to conventional filtration

- Additional energy usage due to pressure-driven operation

- Need for stable pretreatment to control fouling

Plants that treat membranes as a replacement for good design often struggle. Plants that use membranes as a stabilization layer built on top of strong fundamentals usually succeed.

Frequently Asked Questions (FAQ)

. Are inorganic membranes overkill for normal treatment plants?

Not when influent quality is unpredictable, seasonal, or when compliance margins are tight.

Q2. Do membranes reduce operator workload?

Yes, they reduce emergency troubleshooting, but operators must still understand performance trends and cleaning logic.

Q3. How long do inorganic membranes last?

They typically last much longer than polymer membranes when operated within design limits and cleaned correctly.

Q4. Can membranes hide upstream process problems?

No. They often reveal upstream problems through fouling patterns and pressure signals.

Q5. Are inorganic membranes suitable for small plants?

Yes. They work well in small and medium plants where land, manpower, or consistency are constraints.

From an industry standpoint, organizations like Plizma Technology integrate inorganic membranes into water and wastewater treatment systems across industrial and municipal sectors. Their experience aligns with CPCB, SPCB, BIS requirements—reinforcing the importance of strong pretreatment, operator training, compliance monitoring, and lifecycle-focused design.

Learn more:

View Location

RECENT BLOG

What is MBBR Technology in an Sewage Treatment Plant

2026-01-28

What Is a Water Treatment Plant & How it’s works?

2026-01-14

Phosphorus Recovery: Why Wastewater Plants Are the Gold Mines of the Future

2025-12-22

The Hidden World of Sewage: Energy & Fertilizer Generation

2025-12-17