What Is an Effluent Treatment Plant (ETP)? A Complete Guide

2026-02-10 | by Joydip Manna

Quick context first, because theory doesn’t survive on shop floors.

Industrial wastewater is messy. Not textbook messy. Real messy. One shift pH sits at 6.8, next shift it crashes to 3.5 because someone cleaned a reactor. COD jumps without warning, oil shows up from nowhere, color refuses to settle, biology sulks. This is normal. This is what ETPs are actually built for, not ideal lab influent.

An Effluent Treatment Plant is not a formality, not an “inspection-week arrangement”, not a side utility parked near the boundary wall. It is continuous infrastructure. If ETP drifts, production drifts. That link is direct now, no buffer left.

What an ETP Actually Is?

ETP full form: Effluent Treatment Plant.

An Effluent Treatment Plant (ETP) is an industrial facility planned to treat wastewater by separating harmful chemicals, organic matter, heavy metals, and suspended solids. It processes effluent from industries like textiles, pharmaceuticals, and chemicals to make water safe for environmental discharge or reuse. ETPs use physical, chemical, and biological processes to secure regulatory compliance.

Not magically clean.

Not potable.

Compliant. Reusable sometimes, discharge-safe always — if operated properly.

One line that still gets mixed up even today:

ETP ≠ STP

- ETP: Industrial effluent. Chemicals, metals, solvents, variable loads, toxicity.

- STP: Domestic sewage. Toilets, kitchens, stable biodegradable load.

Using STP logic on industrial effluent usually ends with dead biomass, floating sludge, and angry clarifiers. Seen it too many times to be polite about it.

Why Industries Cannot Avoid ETPs Anymore

This is no longer an “environment department problem”.

Regulatory pressure

With online monitoring and OCEMS, SPCBs see outlet data daily. Manual logbooks don’t protect anymore. Norms under Central Pollution Control Board are enforced continuously, not only during inspections.

Operational risk

One violation notice can stop utilities. Not just ETP. Power disconnection is real, and it happens.

Environmental liability

Groundwater contamination doesn’t disappear when production restarts. Liability stays.

ETP failure today is not just an environmental issue.

It is a business continuity issue.

How an ETP Works — What Operators Actually Deal With

1. Preliminary Treatment — Saving Equipment, Not Water

Screens, oil traps, grit chambers.

This stage doesn’t reduce COD on paper, but it saves pumps, pipelines, valves. Miss maintenance here and downstream units pay the price. Always.

2. Primary Treatment — Where Most Problems Start

This stage decides everything later.

Equalization tank

Most critical unit in the plant. Absorbs flow shocks, COD spikes, pH crashes. Plants without proper equalization never stabilize, no matter how advanced downstream tech is.

pH correction

Biology does not forgive bad pH. Neutralization must be steady, not panic dosing after alarms.

Coagulation & flocculation

Color removal, TSS reduction, partial COD drop.

Overdose creates excess sludge. Underdose ruins clarity. Balance matters more than brand.

3. Secondary Treatment — Biology, but Fragile

Activated sludge works only when influent is controlled.

- Solvent shock → biomass dies

- Low DO → filament growth

- High F/M → sludge bulking

Aeration is the biggest power consumer. Most plants either under-aerate to save cost or over-aerate due to fear. Both waste money, differently.

4. Tertiary Treatment — Only When Required

Not every plant needs RO. Many install membranes without fixing upstream instability, then blame membranes.

- Filtration + disinfection for discharge

- UF/RO for reuse or ZLD

Membranes punish poor pretreatment. They don’t forgive.

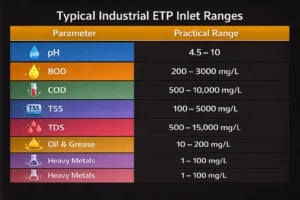

Inlet vs Outlet Parameters — Why Inlet Data Matters More

Regulators look at outlet. Operators must control inlet.

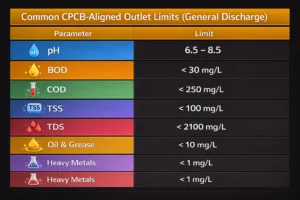

ETP Outlet Parameters (As per CPCB Norms)

Designing an ETP without real inlet sampling is guessing. Guessing fails.

Common CPCB-Aligned Outlet Limits (General Discharge)

Meeting these consistently needs process discipline, not emergency dosing before sampling.

Industry-Wise Pain Points (Ground Reality)

Textile

Color removal harder than COD removal. Salt-driven TDS breaks reuse economics.

Food & Beverage

High BOD is easy. Grease is not. CIP cycles overload systems suddenly.

Pharma / Chemicals

Toxicity matters more than numbers. Equalization and segregation save biology here.

Chemicals — Support System, Not Magic

Alum, ferric, polymers, acids, alkalis, oxidants — all necessary tools.

But chemicals compensate for variability.

They cannot fix poor hydraulic design or missing equalization.

Plants drowning in chemicals are usually hiding upstream problems.

Common Failures Seen Repeatedly

- Excess sludge from blind overdosing

- pH swings killing bacteria overnight

- Hydraulic overloading during peak production

- Aeration blower trips ignored too long

Most failures are operational, not technological.

Sludge — Where Compliance Quietly Breaks

Primary sludge, bio-sludge, chemical sludge. Each needs dewatering and authorized disposal.

Liquid norms may pass, sludge norms fail. Enforcement is shifting here now.

Reuse — Possible, but Conditional

Cooling, gardening, flushing — achievable.

Process reuse needs membranes and discipline.

Unstable ETPs destroy RO systems fast. Very fast.

FAQs

Final Industry Note

What is the difference between STP and ETP?

STP treats domestic sewage from toilets, kitchens, housing colonies using mainly biological processes. ETP treats industrial wastewater, which has chemicals, oils, heavy metals, so chemical + biological treatment both required.

What is the difference between effluent and wastewater?

Wastewater is raw used water generated from domestic or industrial activities. Effluent is treated wastewater, discharged or reused only after meeting pollution control limits.

What is BOD and COD in ETP?

BOD measures biodegradable organic load using oxygen consumed by bacteria. COD measures total organic pollution, including non-biodegradable chemicals, always higher than BOD.

What are the 4 stages of wastewater treatment?

Preliminary (screening, grit removal), Primary (sedimentation, chemical treatment). Secondary (biological treatment), Tertiary (filtration, disinfection, polishing for reuse/discharge).

What are the chemicals used in ETP plant?

Common chemicals include alum, ferric chloride, lime, acids, polymers, nutrients, chlorine. Selection depends fully on effluent nature, pH, COD/BOD load, reuse or discharge requirement.

Conclusion

Effluent Treatment Plants are no longer “environment department equipment”. They sit at the intersection of compliance, ESG pressure, and production stability. Plants that treat ETP as core infrastructure survive audits calmly. Plants that don’t, eventually stop production — temporarily or permanently.

Plizma Technology works in this space daily, across industries and failure modes. Pattern is consistent every time: stable influent control first, treatment efficiency follows. Everything else is noise.

👉 Also read:

How Good ETPs Contribute Largely to Your Company’s ESG Goals

Contact:

Click Here

Last updated on: 2026-02-10

RECENT BLOG

What is MBBR Technology in an Sewage Treatment Plant

2026-01-28

What Is a Water Treatment Plant & How it’s works?

2026-01-14

Phosphorus Recovery: Why Wastewater Plants Are the Gold Mines of the Future

2025-12-22

The Hidden World of Sewage: Energy & Fertilizer Generation

2025-12-17