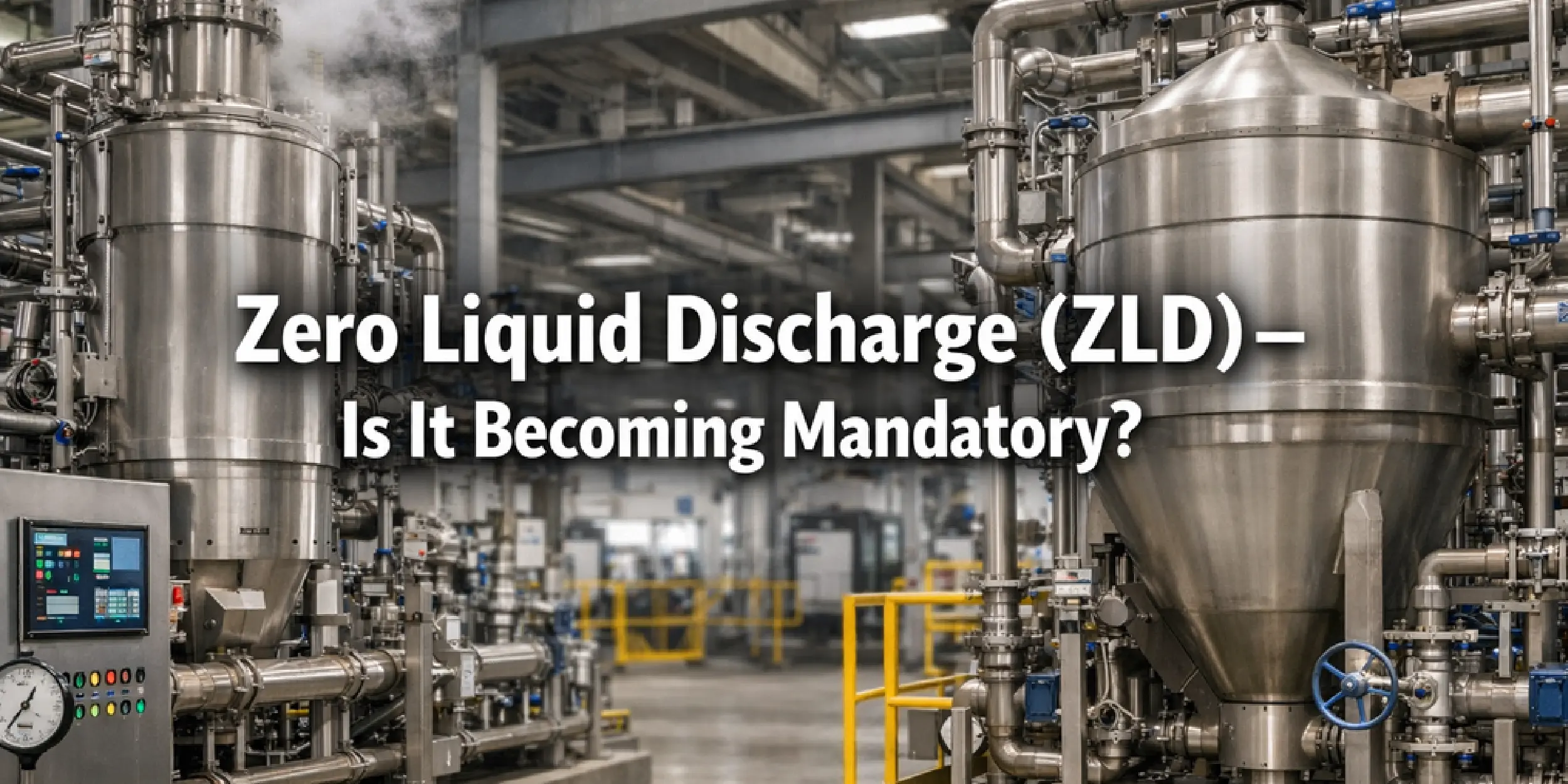

Zero Liquid Discharge (ZLD) – Is It Becoming Mandatory?

2026-02-20 | by Joydip Manna

In last few years, we at Plizma Technology seeing one pattern very clearly. Industries not asking whether to treat wastewater, that part already clear. Now question becoming — is Zero Liquid Discharge compulsory? Is it regulatory pressure or just environmental trend?

Short answer: in many sectors, yes it is moving toward mandatory, but not universally across all industries and locations. Situation is technical and regulatory both, and little confusing on ground.

What is Zero Liquid Discharge (ZLD)?

Zero Liquid Discharge (ZLD) is an advanced wastewater management approach where no liquid effluent leaves the industrial boundary. Entire wastewater is treated, recovered, and recycled. Only solid waste (salts, sludge) remains for disposal.

Technically ZLD includes:

- Primary & secondary treatment (ETP/STP stages)

- Tertiary polishing (UF/RO)

- Multiple Effect Evaporator (MEE)

- Agitated Thin Film Dryer (ATFD) or Crystallizer

- Condensate recovery and reuse

Final discharge: zero liquid. Only solids.

ZLD is not just high-end ETP. It is resource recovery + regulatory shield.

Why Regulators Are Pushing ZLD?

In India especially, groundwater depletion and river contamination forced stricter norms. Regulatory bodies like:

- Central Pollution Control Board (CPCB)

- Ministry of Environment, Forest and Climate Change (MoEFCC)

- State Pollution Control Boards (SPCBs)

have tightened discharge standards under:

- Water (Prevention & Control of Pollution) Act, 1974

- Environment Protection Act, 1986

For certain industries, ZLD is not optional anymore.

Industries Where ZLD Is Already Mandatory (India Context)

- Textile dyeing clusters (Tamil Nadu example)

- Tannery industries

- Bulk drug & pharmaceutical units

- Distilleries (molasses-based)

- Thermal power plants (new installations)

- Chemical manufacturing clusters in critically polluted areas

In several sectors — already mandatory.

Why ZLD Is Becoming Inevitable (Even Where Not Yet Mandatory)

1. Water Scarcity

India entering severe water stress zones (NITI Aayog reports repeatedly). Industrial abstraction limits tightening. Reuse becoming survival issue.

ZLD recovers 90–95% water internally.

2. Stricter Discharge Limits

BOD, COD, TDS limits tightening under CPCB guidelines.

High TDS effluent cannot be biologically treated. Only evaporation-based ZLD solves that permanently.

3. ESG & Global Compliance Pressure

Export-oriented companies must align with ISO 14001, EU environmental directives, and corporate ESG scoring norms.

ZLD gives strong ESG positioning. This is reality at board level discussions.

But Is ZLD Mandatory Everywhere?

No.

Requirement depends on:

- Industry category (Red/Orange/Green)

- Effluent characteristics (especially TDS)

- Location (critically polluted area or not)

- Groundwater extraction dependency

- SPCB consent conditions

No blanket rule for all industries.

Global Scenario

USA

Under United States Environmental Protection Agency (USEPA), ZLD not universally mandatory. But specific sectors under ELG face tight discharge norms pushing toward evaporation systems.

Europe

EU Water Framework Directive pushing zero pollution goal, but ZLD not blanket rule.

Middle East

In water-scarce regions, ZLD increasingly preferred due to reuse economics.

Globally trend is upward, but sector-based.

Technical Reality: ZLD Is Expensive

CAPEX:

- Evaporators energy intensive

- Crystallizers costly

- High steam consumption

OPEX Challenges:

- Scaling in MEE

- High power usage

- Skilled maintenance needed

- Salt disposal logistics

Many plants fail not due to regulation, but poor design or improper O&M planning.

When Should Industry Move Toward ZLD?

Move toward ZLD if:

- TDS > 10,000 mg/L

- Located in water-scarce belt

- Discharge route uncertain

- Export-driven compliance pressure

- Groundwater extraction restricted

Avoid blind installation if:

- Low TDS biodegradable effluent

- Stable discharge permission available

- Water availability not critical

Engineering decision must be data-driven.

Practical Process Flow of a Typical ZLD System

- Equalization

- Physico-chemical treatment

- Biological treatment (if needed)

- Ultrafiltration (UF)

- Reverse Osmosis (RO)

- RO reject → MEE

- MEE concentrate → ATFD/Crystallizer

- Condensate reuse

Water recovery up to 95–98% possible in optimized systems.

Trade-Offs

| Factor | ZLD Advantage | ZLD Challenge |

|---|---|---|

| Compliance | Near-zero discharge risk | High CAPEX |

| Water Reuse | 90–95% recovery | Energy intensive |

| ESG Rating | Strong improvement | Skilled O&M required |

| Long-Term Risk | Reduced regulatory shutdown | Salt disposal complexity |

FAQ

Is ZLD compulsory as per CPCB?

CPCB mandates ZLD for specific high-pollution industries like textile dyeing, tannery, distillery, and certain pharma clusters. Not blanket for all industries.

Does MoEFCC mandate ZLD for all new industries?

MoEFCC does not universally mandate ZLD. Environmental Clearance conditions may require it based on pollution load and location.

What recovery percentage is achievable in ZLD?

Typically 90–95%. Advanced systems may reach 98% with higher OPEX.

Is ZLD economically viable?

For water-scarce regions and high TDS effluent industries — yes long-term viable. For low-pollution industries, conventional ETP may be sufficient.

Final Industry Note

Zero Liquid Discharge is not hype anymore. It is moving from optional environmental strategy to regulatory expectation in multiple sectors. Not universal mandate yet, but direction is clear.

Decision must be engineering-based, regulator-aligned, and financially calculated — not panic-driven.

At Plizma Technology, we see this shift happening plant by plant. The question is not “if” in many sectors, it is “when”.

Industries that prepare early design properly. Those that delay often forced under compliance deadlines, which becomes costlier.

Time window still there. But narrowing.

👉 Also read:

What Is an Effluent Treatment Plant (ETP)? A Complete Guide

Contact:

Click Here

Last updated on: 2026-02-20

RECENT BLOG

Top 10 Water And Wastewater Treatmant Plant Manufacturer in Eastern India

2026-02-12

What Is an Effluent Treatment Plant (ETP)? A Complete Guide

2026-02-10

What is MBBR Technology in an Sewage Treatment Plant

2026-01-28

What Is a Water Treatment Plant & How it’s works?

2026-01-14